XAVIER OLIVER'S WEB PAGE

DESCRIPTION OF THE PROJECT:

Grant Agreement Number: 779611

Financial Institution: European Research Council - European Commission.

Starting time: 01/01/2018

Ending time: 30/06/2019

Budget: 149.991 €

DESCRIPTION OF THE IDEA:

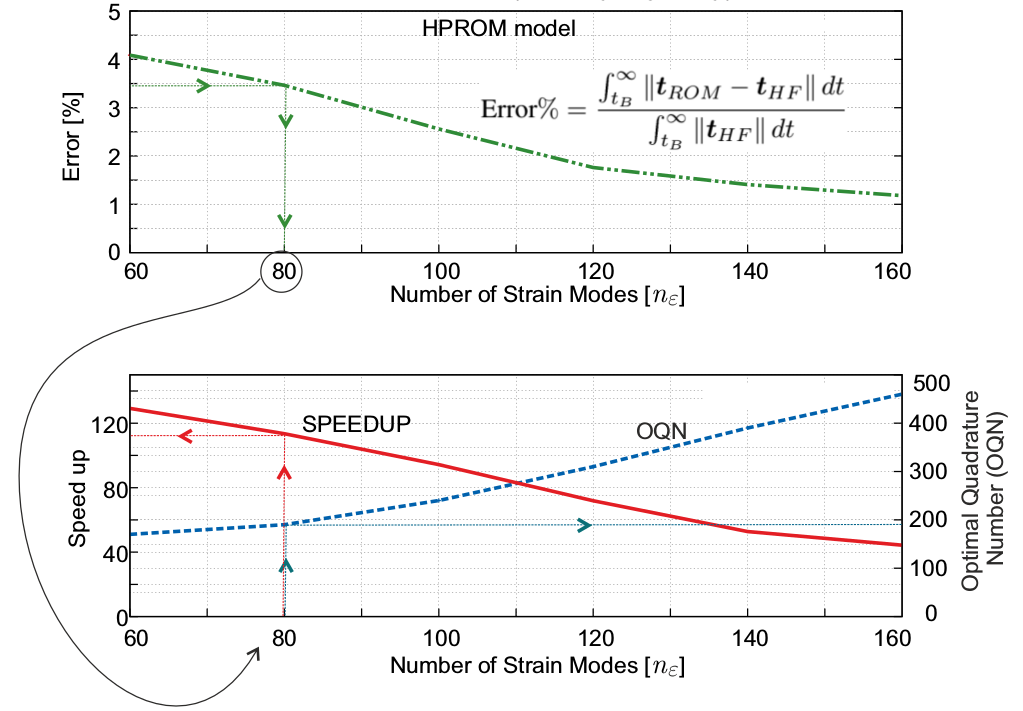

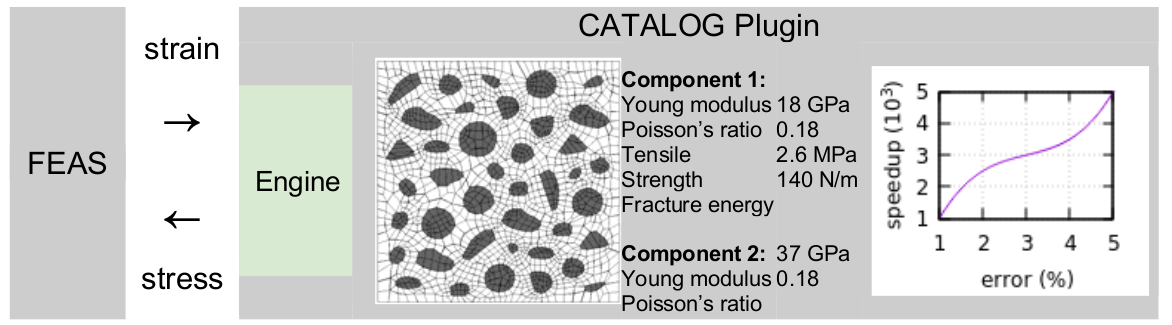

In the present Proof of Concept CATALOG, we will explore the industrial applicability and potential for commercialization of a prototype of a “computational multiscale material catalog”, to exploit HPROM (high-performance reduced order modeling), a technology developed in the ERC Advanced Grant COMP-DES-MAT for advanced material simulation. CATALOG will provide extremely fast and accurate multiscale capabilities to existing commercial Finite Element Analysis Solvers (FEAS), greatly enhancing their standard simulation performance. Implemented as a plugin, the coupling CATALOG‐FEAS will be completely noninvasive and adaptable to most commercial FEAS.

INNOVATION POTENTIAL:

The use of multiscale representation of the material in finite element solvers has been a long-sought purpose in industrial simulation. Multiscale technology was developed in response to the increasing use of advanced fiber-reinforced composites mainly in automotive, aerospace and military applications. Multiscale material technology quickly expanded to a wider selections of materials besides composites, as many other materials used in engineering (e.g. concrete, structural metals) are also inherently heterogeneous, and present a mechanical and fracture behavior which is fundamentally governed by their microstructure.

Pioneering multiscale implementations —known as “High Fidelity” (HF)— involve an enormous computational cost, due to the dense finite element meshes required for a realistic representation of the material at the microscale, and to the fact that they require a full nonlinear finite element simulation at every point of the macroscale mesh and for every single time and iteration of the analysis

In practice, it has become evident that the costly HF simulations are not useful in the industrial setting. As an example, an analysis involving HF simulations may typically take months to complete in standard computing clusters, a time far too long for routine use. For practical purposes, such analysis should be reduced from months to hours. The industrial requirements are clear: physically accurate tools that account for microstructural design variables with a reduction in time of at least 5000-fold.

ECONOMICAL AND SOCIETAL BENEFITS:

Up to this day, there is no FEAS or equivalent product available to the industry that is able to reach the levels of detailed simulations at affordable computational costs required by design and manufacturing sectors. The CATALOG PoC will package the HPROM software technology into an application with tangible and immediatebenefits to the industrial field. A number of new applications involving complex material simulation will profit from CATALOG. As a matter of example:

● Virtual testing, a trending methodology in aerospace industry, in which the experimental tests are substituted for simulated tests. Virtual tests are carried out in the inelastic range of the tested component, to study mechanical failure modes of the material (e.g. delamination, fatigue, buckling.) Today, the main challenge of these simulations is the lack of realistic representations of the complex behavior in these ultimate states of the material. This aspect is at the very core of COMP-DES-MAT capabilities. CATALOG can provide a faithful approximation to reality, due to the inclusion of multiscale effects and the accurate description of the ultimate ranges of the material strain.

● Advanced manufacturing technologies with change of phase in the material (e.g. additive manufacturing, hot-pressing technology, powder metallurgy, stamping industry), as modeling a material undergoing a phase change relies on a large number of internal variables. Multiscale simulations are able to accurately describe this evolution at highly reduced computational costs.

● Novel metamaterials design. Metamaterials —i.e. artificial materials with exhibit exceptional properties not readily observed in nature, such as programmable shape and function— require the use of multiscale tools for their design. Multiscale simulations allow the design and further optimization of the microscale topology and morphology to achieve the intended goals at the macroscale. Given the current progress in additive manufacturing techniques, CATALOG will help this promising industry move forward by providing

suitable design tools which are currently unavailable.

ERC PROOF OF CONCEPT - CATALOG